The road into Ute’s mill and farm is lined with beautiful trees on either side. At the end of the road, you are greeted by her two dogs and if you are lucky, her pet pig Bernie. As we head into her mill we start chatting about her background, running her mill and all of the projects she has on the go. It is quickly clear that in all her work, Ute has a high attention to detail and does not shy away from a challenge.

Written and Photographed by Emily Neill

Where did you grow up?

I was raised in Bavaria/Germany between Munich and Salzburg, but went to school in Munich.

You raised goats for many years, what caused you to switch to fibre animals?

Getting older and realizing there is a limit what I can do caused me to switch. Milking goats twice a day takes a lot of commitment keeping me tied down to the farm a lot. I couldn’t go out for dinner and no matter how I felt (sick or not), I had to go out there to milk the goats. Besides that, the laws for food are very tough. It was a constant battle with inspectors because they didn’t understand farming or organic at all. Compared to goats, fibre animals are not restricted to be fed at a certain time and besides shearing there is not much stress.

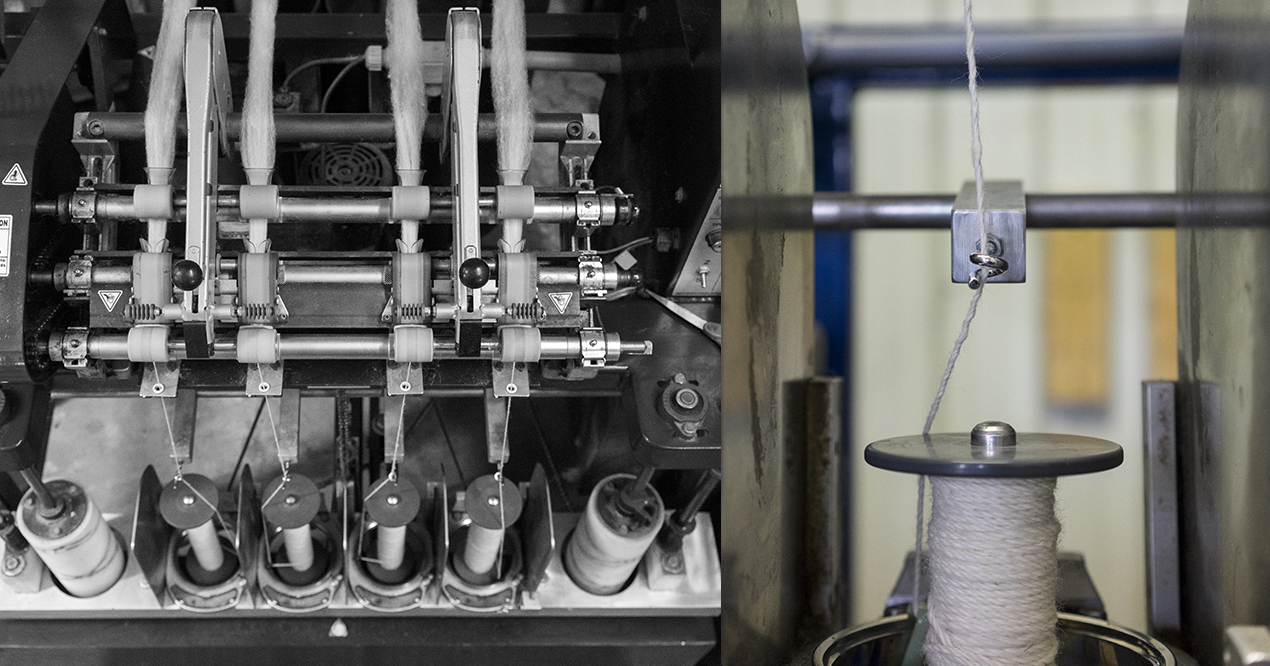

Along with raising animals, you process fibre. Can you tell us a little bit about how yarn is processed?

1. Weigh the fibre and decide what kind of yarn you would like to produce.

2. Wash the fibre, making sure it’s really clean so it doesn’t cause trouble during processing.

3. Spread the fibre on the drying rack to dry.

4. Send it through a machine called a picker to loosen it up. (Photo below)

5. If desired by the customer separate the guard hair from the undercoat with the fibre separator. This is basically necessary with llama, alpaca (older or less quality animals), cashmere etc.

6. Card the fibre into rovings.

7. Send the roving through the draw frame 2 – 3 x sometimes more often, to eliminate unevenness for spinning. This is especially necessary for fine yarn.

8. Spin the roving into a single ply yarn also know as a single. (photo below)

9. Ply singles together into a 2-ply or 3-ply yarn and balance it.

10. Send the yarn through the cone winder, which transfers the yarn from the bobbin onto a cone.

11. Send the yarn through the steamer to set the twist.

12. Send the yarn through the skein winder and tie it.

13. Twist the yarn into skeins and label.

With both animals and a processing facility your days must be busy. What does a standard day look like for you?